We are one of the UK’s Leading Fibre Cement Sheet Suppliers.

As one of the leading fibre cement sheet suppliers in the industry, we only source quality fibre cement cladding boards. PIRS will help you choose the right solution for your roofing and cladding projects.

As such, we stock a variety of competitively priced fibre cement cladding and fibre cement sheeting products to choose from. Because of this, whether you’re looking to replace corrugated sheets on garages and agricultural buildings, or you’re looking for a denser Cemsix fibre cement sheeting profile, we’ve got it covered. In fact, we have all the accessories, screws and fixings you’ll need!

We partner with manufacturers whose fibre cement board products offer practical high-performance solutions. This means you can have total confidence in our cement board cladding, fibre cement sheeting, panels and roofing cement boards. Additionally, many of our products come with extensive manufacturer warranties – some for up to 30 years.

Specialist Fibre Cement Sheet Suppliers

We offer our customers the advantage of being able to obtain all the products, tools, and equipment they require from a single, reputable source. As fibre cement sheet suppliers, our close links with major manufacturers mean that we can provide quality products at competitive rates. Every day we introduce new fibre cement cladding product lines, such as Cembrit and many more. As a result, you can purchase all your supplies from us, including materials, accessories and fixings.

If you’re unsure what you need, or you expect the building use to change over time, we can advise. Best of all, we’ve made the purchasing process simple. Since we have many years of experience in the trade, we coordinate your deliveries to help keep your project on track. Our national logistics network delivers the fibre cement cladding products you require quickly, easily, and cost-effectively. When you choose Prestige, you choose quality and service.

Fibre Cement Sheeting FAQs

What are the different types of fibre cement boards?

Fibre cement boards, also known as fibre cement panels, are a versatile composite construction material used in roofing and façade building products.

Ever since they were developed in the early 1980s, they’ve been used for their strength and durability. Fibre cement sheeting is made up of cellulose fibre (the filler), cement (the binding agent), sand and water. There’s a small amount of other chemical additives too to help the binding process.

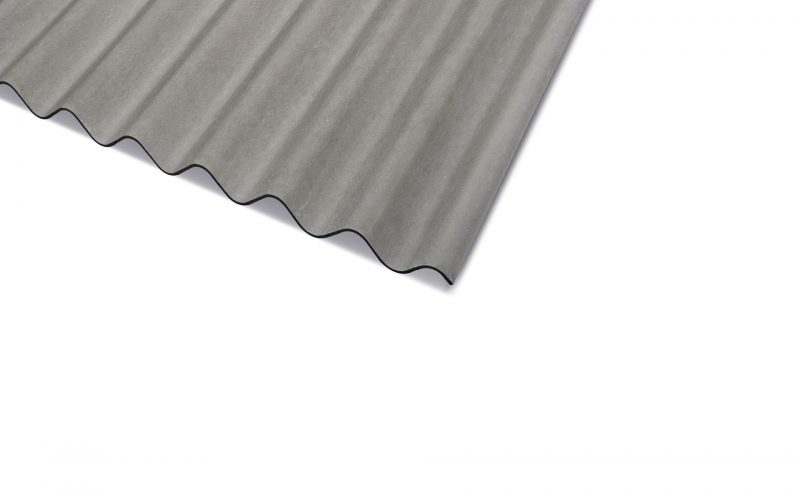

Once the fibre cement has been made, it is rolled into fibre cement sheeting and compressed to draw out moisture. If the intended use is on an industrial roof, the fibre cement panels are shaped into a corrugated box profile for added weather resistance. To improve the visual appeal of cement board cladding, there’s a wide range of paints and finishes that can be applied at the manufacturers, such as natural grey.

As leading fibre cement sheet suppliers, we supply some of the very best fibre cement sheeting on the market. One of our most popular systems is Cemsix (Profile 6) fibre cement sheeting. Cemsix is much denser than its semi-compressed counterparts and is therefore highly durable. It is also available in a wide range of colours, including low sheen natural grey and anthracite. Moreover, the Cemsix roofing cement board system is covered by the BBA Agreement Certificate 03/4049 and is guaranteed for 30 years.

For smaller, single skinned structures and single storey roofing, Cembrit B5 is a good fibre cement sheeting system as it’s great at preventing rust and rot and absorbing condensation. It’s just the right fibre cement panels product if you’re looking to replace 3” corrugated sheets on garages or agricultural buildings.

What are the main characteristics of fibre cement sheeting?

Fibre cement sheeting is chosen as a roofing and façade building product for a whole host of reasons, and here are the main ones:

- Fibre cement panels are water resistant

- Fibre cement itself does not burn, it is a non-combustible building material

- Fibre cement sheeting is UV resistant and far less prone to warping

- Roofing cement boards are easy to install and for this reason is often chosen over timber cladding

- Stands up to the harshest weather conditions, from severe frosts to high winds and heavy rain

- Fibre cement board is also a very lightweight material – it is thinner than concrete yet has the same performance benefits

What are the advantages of fibre cement boards?

From their durability and strength to sustainability and fire safety, fibre cement boards enjoy many practical benefits.

Durability

Fully resistant to rot, mould, moss and algae, fibre cement sheeting products are incredibly resilient. Quite simply, there’s no risk of shrinkage or warping due to thermal movement. Moreover, roofing cement boards do not rust, and are immune to fire or chemical damage.

Ventilation

Fibre cement sheeting can significantly enhance ventilation levels in a building, making it ideal for housing livestock. When installed correctly, roofing cement boards help a building to breathe by increasing airflow.

Non-Combustible

An extremely important feature and one of the main reasons fibre cement sheeting is chosen is that fibre cement boards do not burn. Instead, they hold back flames. Many are fire Performance rated as A2 according to BS EN 13501-1, SAA and Class 0.

Watertight

Due to the use of sand in its construction, fibre cement cladding repels water to make a roof or façade weather resistant. Moreover, fibre cement panels are UV resistant, so colours like natural grey do not fade.

Lifespan

Another well-known advantage of fibre cement cladding and roofing products is their life expectancy. Although manufacturer warranties tend to be for 25 years, they can last upwards of 50 years. This makes fibre cement boards an ideal choice for agricultural and industrial buildings whose owners want minimal upkeep.

Low Maintenance

Roofing cement boards require virtually zero maintenance, although they will need to be cleaned if you want them to continue to look good.

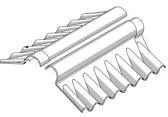

How must you install and store fibre cement boards?

Thankfully, fibre cement sheeting is straightforward to install due to its light weight, which makes it easy to handle and transport. Plus, most fibre cement boards and panels are available in large sizes, which speeds up the installation process.

If you haven’t taken delivery of fibre cement boards before, here are a couple of tips on storage, which as leading fibre cement sheet suppliers we like to share with our customers.

When the fibre cement cladding arrives make sure you check it for any damage – although our delivery drivers are very careful! Also make sure you keep it off the ground and dry until it is installed. Carry large fibre cement boards from the edges to prevent breaking and support them along the length when cutting.

The right cutting tools are essential for this notoriously strong material, which we can also source as fibre cement sheet suppliers. When cutting large sections, it is best to use a polycrystalline diamond blade to cut fibre cement cladding or sheeting since the diamond-tipped teeth of the blade make the job far easier and safer. If you need to make small angled cuts, you can generally use the score and snap method using a carbide cutter, but it all depends on the thickness of your chosen fibre cement panels.

What are the fire resistance properties of fibre cement cladding?

Thankfully, fibre cement sheeting is straightforward to install due to its light weight, which makes it easy to handle and transport. Plus, most fibre cement boards and panels are available in large flat sizes, which speeds up installation.

If you haven’t taken delivery of fibre cement boards before, here are a couple of tips on storage, which as leading fibre cement sheet suppliers we like to share with our customers.

When the fibre cement cladding arrives, make sure you check it for any damage – although our delivery drivers are very careful! Also make sure you keep it off the ground and dry until it is installed. Carry large fibre cement boards from the edges to prevent breaking and support them along the long edge when cutting.

The right cutting tools are essential for this notoriously strong material, which we can also source as fibre cement sheet suppliers. When cutting large sections, it is best to use a polycrystalline diamond blade to cut fibre cement cladding or sheeting since the diamond-tipped teeth of the blade make the job far easier and safer. If you need to make small angled cuts, you can generally use the score and snap method using a carbide cutter, but it all depends on the thickness of your chosen fibre cement panels.

What are the fire resistance properties of fibre cement cladding?

As fibre cement sheet suppliers we are often asked about the fire rating of fibre cement cladding, boards, panels and sheeting. Fibre cement cladding is exceptionally good at preventing the spread of fire because the material it is made from is non-combustible. This means that fibre cement sheeting will not ignite when exposed directly to a flame or heat, and neither will it add fuel to a fire.

Most fibre cement boards that we supply are Euro Class A1 fire rated meaning that they provide the highest level of fire rated performance in the building world. Along with this, for many products, a fire insulation burn time can be up to two hours, making it a preferred building material for buildings at higher risk of fire.

In fact, the majority of fibre cement cladding products are A2-s1, d0 rated, which when broken down means:

- A2 refers to the flammability of the product – it is non-combustible therefore does not catch fire very easily.

- The S-value relates to smoke development from a fire. S1 means that you would expect barely any smoke from fibre cement cladding.

- The value d0 refers to the amount of burning drops you see in a fire, which with fibre cement boarding is 0.